Cp stands for process capability and Cpk stands for process capability index. Both are used for the measure of a potential capability of a process in short term. The higher the sigma level, the better the process is performing. You can learn how to calculate Cp and Cpk values using this tutorial. Learn to calculate the Process Capability (Cp) and Process Capability Index (Cpk) values using the steps and few examples given here.

Learn to Calculate Process Capability Index - Tutorial, Definition and Example

Process Capability (Cp) Definition:

How to Determine Bin Intervals to Create a Histogram in Excel Bin intervals need to span enough distance to include the upper and lower spec limits and the min and max values. Using the data in the previous example, follow these steps to determine bin intervals for a histogram.

Process capability is a technique to find out the measurable property of a process to a specification. Generally, the final solution of the process capability is specified either in the form of calculations or histograms

Process Capability Index (Cpk) Definition:

- Cpk Analysis u Chart c Chart np Chart p Chart XbarS XbarR Sheet2 IMR Sheet32 Sheet29 Sheet1 Sheet16 Sheet18 Sheet20 Sheet28 Sheet30 Sheet31 Sheet33 Sheet34 Sheet35 SPC XL Sheet9. SPC XL 2010 for Microsoft Excel.

- The process capability is a measurable property of a process to the specification, expressed as a process capability index (e.g., Cpk or Cpm). The output of this measurement is usually illustrated by a chronological control sample, histogram and calculations that predict how many parts will be produced out of specification (.

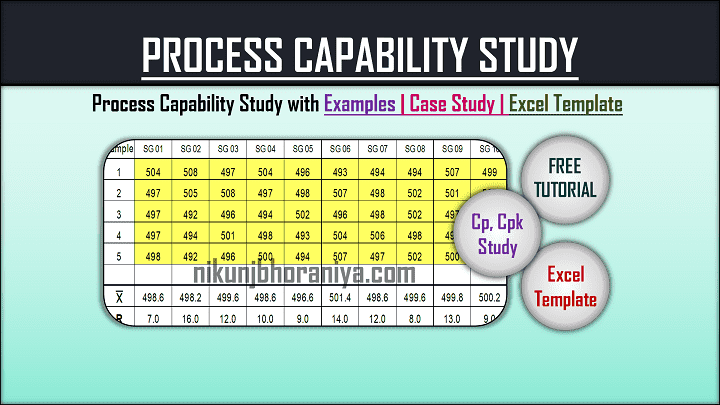

- SPC Format DOWNLOAD Excel Template of SPC Study: SPC Format is commonly used in the industry to know Process capability and how well the process Performs to meet the requirements. SPC study consists of 1 Control Chart 2 Process Capability.

Process capability index (cpk) is the measure of process capability. It shows how closely a process is able to produce the output to its overall specifications.

Formula :

Where,

USL = Upper Specification Limit, LSL = Lower Specification Limit.

Example :

Food served at a restaurant should be between 38°C and 49°C when it is delivered to the customer. The process used to keep the food at the correct temperature has a process standard deviation of 2°C and the mean value for these temperature is 40. What is the process capability of the process?

Given,

USL (Upper Specification Limit) =49°C LSL (Lower Specification Limit) =39°C Standard Deviation =2°C Mean = 40

Cpk Calculation Excel Template Free

To Find,

Process Capability & Process Capability Index

Solution:

| Process Capability : | |

|---|---|

| Process Capability | = (49 - 39) / (6 * 2) |

| = 10 / 12 | |

| = 0.833 | |

| Process Capability Index : | |

| Solution 1 | |

| (USL-mean/ 3*std.Dev) | = (49 - 40) / (3 * 2) |

| = 1.5 | |

| Solution 2 | |

| (mean-LSL/3*std.Dev) | = (40 - 39) / (3 * 2) |

| = 0.166 | |

| Now, find the minimum value. | |

| Process Capability Index | = min (Solution 1, Solution 2) |

| = min (1.5 , 0.166) | |

| = 0.166 | |

Cp and Cpk are used in Six Sigma Quality Methods for analyzing the performance of the process carried out to deliver any product.

Cpk Calculation Excel Template

Related Tutorials:

Top Calculators

Popular Calculators

Top Categories

What is Ppk?

Our first two blogs in this process capability series answered two questions: What is process capability? – and - What is Cpk? This blog answers the next question: What is Ppk?

The answer is quite simple. Just to refresh your memory, Cpk is expressed as the following:

Cpk = Minimum (Cpu, Cpl)

Cpu=(USL-X)/3σ

Cpl=(X-LSL)/3σ

where Cpu is the capability based on the upper specification limit (USL), Cpl is the capability based on the lower specification limit (LSL), X is the overall average, and σ is the estimated standard deviation from a range control chart. Cpk is the minimum of Cpu and Cpl.

Ppk is expressed as the following:

Using Excel To Calculate Cpk

Ppk = Minimum (Ppu, Ppl)

Ppu=(USL-X)/3s

Ppl=(X-LSL)/3s

where Ppu is the capability based on the upper specification limit (USL), Ppl is the capability based on the lower specification limit (LSL), and s is the calculated standard deviation from all the data. Ppk is the minimum of Ppu and Ppl.

Look at the equations for Cpu and Ppu. What differences do you see? Now look at equations for Cpl and Ppl. What differences do you see?

The only difference is that Cpu and Cpl both use σ - the estimated standard deviation from a range control chart, while Ppu and Ppl both use s - the calculated standard deviation from all the data.

What does the difference mean? The easiest way to see this is through an example using an individuals control chart (X-mR). With an individuals control chart, the individual (X) value is plotted on the X chart. The range between consecutive points is plotted on the moving range (mR) chart. The average moving range is used to calculate the value of σ. And this value is used in the Cpk calculations.

Suppose the data are being collected hourly. Each moving range represents the “short-term” variation – the variation between consecutive hours. Cpk is sometimes referred to as the short-term capability – it represents what the process is capable of doing in the short-term – from hour to hour in this example.

| Hour | X | Hour | X |

|---|---|---|---|

| 1 | 106 | 11 | 102 |

| 2 | 104 | 12 | 100 |

| 3 | 104 | 13 | 92 |

| 4 | 106 | 14 | 99 |

| 5 | 99 | 15 | 115 |

| 6 | 92 | 16 | 105 |

| 7 | 99 | 17 | 100 |

| 8 | 93 | 18 | 98 |

| 9 | 109 | 19 | 105 |

| 10 | 105 | 20 | 99 |

The figure below represents the moving range for the data given. The first X value is 106; the second X value is 104. So, the moving range between these two results is 2.

The average moving range for these data is 6.2. For a moving range between consecutive points, σ is calculated as the following:

How To Compute Cpk In Excel

σ = R/1.128 = 6.2/1.128= 5.50

This is the value that would be used in calculating Cpk.

For Ppk, the standard deviation of all the X values is calculated. Note that all the values are used at one time to determine the standard deviation. These values represent 20 hours (since there are 20 data points). This is a much longer time-frame than the between consecutive hours in the moving range chart. Because of this, Ppk is sometimes referred to as the long-term capability. In Excel, you can use the function STDEV to calculate the standard deviation. The result is:

s = 5.7

This is the value that would be used in calculating Ppk

The difference between Cpk and Ppk is simply in how you calculated the standard deviation. So, which is better to use: the short-term Cpk capability or the long-term Ppk capability? This will be the topic of our next blog.

Our SPC Knowledge Base has multiple publications on process capability if you would like more details.

The control chart above was made using SPC for Excel, a simple but powerful software for statistical analysis in the Excel environment.